If you want to start a brewery,BIAC will be your best choice.

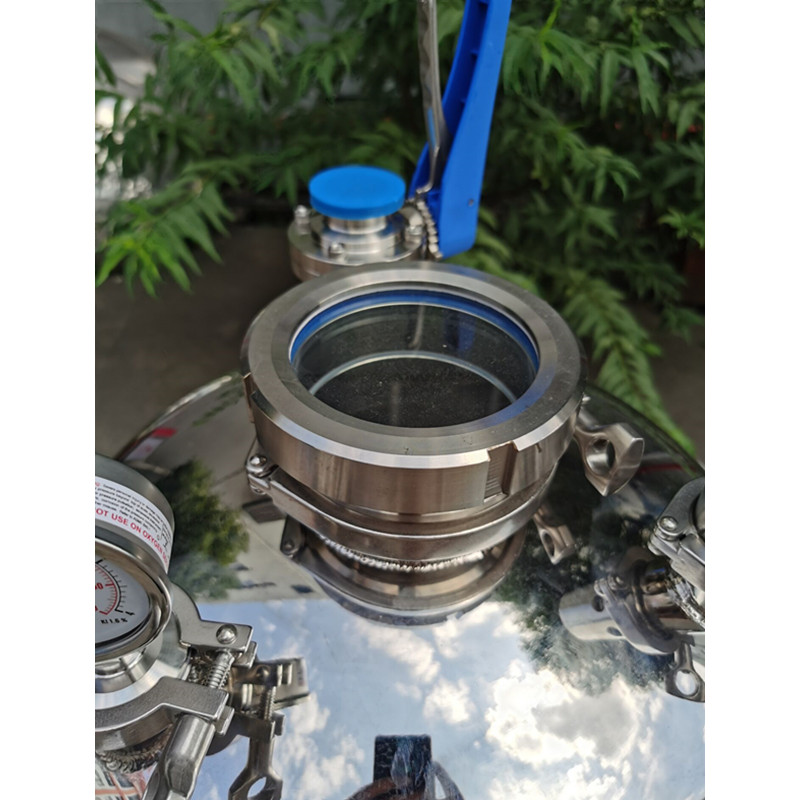

This is an unique 5 in 1 beer brewing system(mash,boil,ferment,carbonate,serve).

Benefits of BIAC:

1)The smallest brewing area needed,due to brewing beer in a single conical fermenter,no need the hot liquor tank,mash lauter tun,boil kettle,you will save around 70% floor space for brewhouse areas.

2)Less water,less chemicals and less wastes,

Uses 67% less water; while traditional brew systems use approximately 5-7 pints of water for every pint of beer produced, the BIAC needs less than 2 making it have the lowest water demand of any brewing system; with the heat of the boil sanitizing the system, the extensive chemical scrubbing, cleaning, rinsing and sanitizing that wastes all that water is no longer needed.

3)Good sanitation (preventing harmful microorganisms from entering) is the most critical factor in making good beer. The BIAC fermenter doubles as a boiling kettle and the heat from each boil will provide perfect, chemical-free, thermal hygiene. No need for chemical cleaners and disinfectants like other brewing systems, saving time and money and giving you peace of mind that your beer tastes its best (nasty chemical residues won't be in your beer)!

4)Scaleable and expandable,we have lots of size in range and you just need to add more BIAC conical fermenter will be fine.

5)Saving cost,more economical,save more than 30% of the capital and installation costs than similar systems. Although it is made of the highest quality materials, it costs much less than a complete traditional container system due to fewer containers, less supporting hardware, less installation and maintenance costs, and less labor.

6)Saving time,shorter brew day and lower labor cost

Due to less vessels to operate and clean,less brewing steps in the brewing process.

7)Multipurpose

All types of beer can be produced, and because the brewer has almost unlimited control over the brewing process (which can also be used to produce wine, or even spirits, with an optional shotgun condensing assembly) and thermal hygiene, styles like kettles can be brewed safely in the same equipment without fear of microbial cross-contamination.

8)Automatic temp control,we will install the automatic temp control for the system without PLC,it will help us to do the aftersales services

9)Minimal oxidation and contamination risk

Less transfer,the BIAC system has a minimal risk of oxygen and microbial exposure, ensuring you deliver the freshest, tastiest beer to your customers.